-How

To Install Goldpoint 24-Position Stepped Attenuators and Selector

Switches: -How

To Install Goldpoint 24-Position Stepped Attenuators and Selector

Switches: |

| The front metal sections

of Goldpoint 12 and 24 position rotary switches were ingenuously designed in Switzerland

or Germany around 1960. A protruding, pointed tab (labeled "Locking Key"

below) was

employed as an anti-rotation feature. This works great, but entails a

little bit more attention to mounting these units on a panel than

simply drilling a hole and tightening a hex nut. Very

Important! The

most common error made when installing one of these units is to fail

to: |

| 1) Use a second hex nut inside the mounting panel - as shown in Mounting

Method #1. |

| 2) Or cut or file a channel (keyway in the panel) for the locking key to

fit into - as shown in Mounting

Method #2. |

3) Or file off the protruding locking key - Mounting

Method #3. This is usually OK because our audio stepped attenuators and selector

switches have a lot less turning torque than the original switches in

the 1960s, so you don't really need the locking key now. (While filing

off the protruding key, clamp the switch shaft (only) in a large,

stable vise.)

|

|

|

| Mounting

Method 1:

If the panel you are mounting to is thin: up to 0.07", (1/16"), (1.5

mm),

you can mount the unit using two hex nuts and a flat washer. This is the

preferred and easiest mounting method. |

| Important:

Never

allow the tip of the locking key to touch the inner hex nut - doing so

could warp

and damage the unit. |

|

|

|

|

|

|

| Mounting

Method 2:

If the panel is thicker than 0.07", up to 0.255" (6.5mm), mount the unit with only one hex

nut

and a flat washer. Make

a notch in the mounting

hole - as shown at left under "Mounting

Hole with Keyway". |

| Important: Never

allow the locking key tip to touch the inside of the mounting panel -

doing

so could warp and damage the unit. |

| Mounting

Method 3: File

off the protruding locking key - whether the mounting panel is thin

or thick. Mount in round hole, no notch, with one or two hex nuts and a

flat washer - as

shown at left. Before filing, wrap the rest of the unit with kitchen

plastic wrap to ensure the filings do not get into the switch

contacts. |

|

|

Mounting

Hole for Goldpoint

47-Position Stepped Attenuators: Mounting

Hole for Goldpoint

47-Position Stepped Attenuators:

|

|

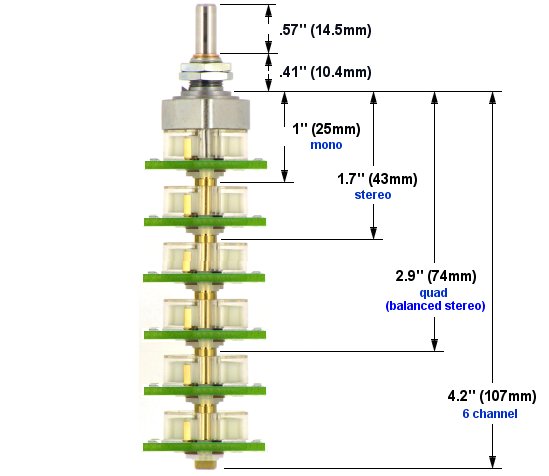

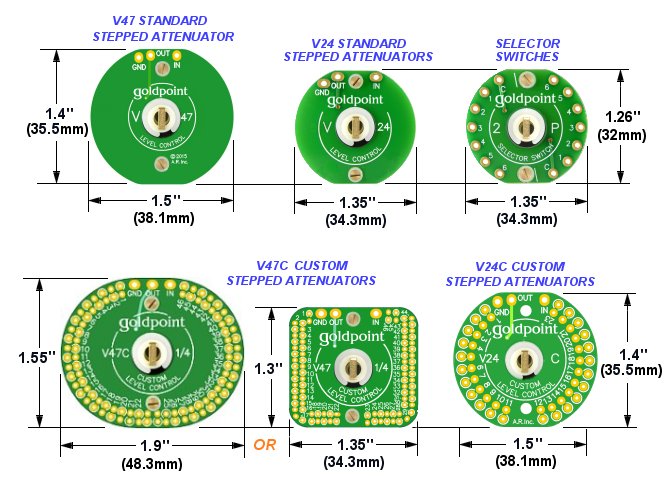

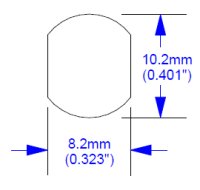

Our

47-Position stepped attenuators use a "Double-D"

panel cutout as an anti-rotation feature. Our

47-Position stepped attenuators use a "Double-D"

panel cutout as an anti-rotation feature.

However, because

our rotational torque is fairly low, you can simply mount them into a

round hole (diameter = 0.401" or 10.2mm).

If you use a round hole, place a lock-washer on the threaded

bushing before

sliding it into the front panel or put a flat washer under the hex nut on the outside of the front

panel. However, because

our rotational torque is fairly low, you can simply mount them into a

round hole (diameter = 0.401" or 10.2mm).

If you use a round hole, place a lock-washer on the threaded

bushing before

sliding it into the front panel or put a flat washer under the hex nut on the outside of the front

panel.

Maximum panel thickness is about 0.255" (6.5mm) if you mount the attenuator with a hexnut and one flat washer. Maximum panel thickness is about 0.255" (6.5mm) if you mount the attenuator with a hexnut and one flat washer. |

|

|

| Mounting Data in Acrobat PDF file |

|