-How

To Choose the Correct Stepped Attenuator Value. General Rules and

Considerations: -How

To Choose the Correct Stepped Attenuator Value. General Rules and

Considerations: |

1)-When

upgrading from a potentiometer, use the same value stepped attenuator.

(5K,

10K, 25K, 50K, 100K, etc.)

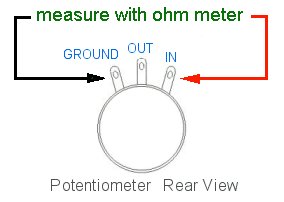

If you need

to find the potentiometer value by measuring it:

1) Unplug the equipment from any AC source.

2) Unsolder two of the three wires going to one channel of your

potentiometer. (It does not matter which two wires.) |

|

| 2)-Matching

the volume control value to the amplifier/pre-amplifier input impedance

is not as important as some people think, so you typically don't really

have to worry about this. For a 100K

input impedance, use a 100K, 50K, 25K, or even a 10K level

control. This applies to passive preamps, active preamplifiers, and power

amplifiers when the control is to be installed at the Input. Check your

owner's manual to find the the rated Input Impedance of your unit, or

contact

the manufacturer directly. Our 25K stepped attenuator usually value

replaces replaces 20K potentiometers. |

| 3)-Regarding

the choice of stepped attenuator values in Goldpoint SA1, SA2,

SA4

(25K) and SA1X, SA2X (10K), much

observation and thought has gone into this over many years. We

concluded

that the values which we are using for our standard off-the-shelf

passive

preamps and precision level controls should not

be changed (unless really necessary or preferred for some other

reason).

Lower stepped attenuator values make

them

more compatible with a wider range of power amplifier Input impedances

- which they might encounter

over time. |

|

Notes:

One common

opinion states that with the higher

value level controls, such as 50K and 100K, you can hear higher

amounts of (desirable) high frequency harmonics, or even that "it

sounds

more open and airy". A similar opinion states that the lower

values, such as 10K and 25K sound

slightly "richer" or "more full bodied". The actual truth may depend on

the equipment being listened to and/or which set or ears is doing the

listening.

I have found that the stepped attenuator (volume control) value is

usually

not so critical - and that it does not make as much difference as some

people

claim - but that other aspects of the equipment or system can make

bigger,

more noticeable sonic differences. |

| There

is a common misconception that higher value volume controls such as 50K

or 100K will result in LOUDER sound compared to using 10K or 25K volume

controls. This is not true. 10K controls usually yield exactly the same

loudness as 100K units. (Technically, there are other reasons why

different

value controls are used in different places or applications.) |

| Vacuum

tube equipment often uses 25K, 50K,

or 100K level controls, due to the high input impedance of

tubes.

Solid-state gear usually has 10K, 25K,

or 50K level controls. |

| You

can begin to have "high frequency roll off" beginning to appear with

volume

control values above 100K. If you don't have an engineer handy, or just

can't decide,

25K is a good choice

for both vacuum tube and solid-state equipment, especially for passive

level controls. |

| We use the

25K

stepped attenuator value in our home audio (RCA connector) SA1, SA2,

and

SA4 passive preamps. Our balanced (XLR connector) SA1X and SA2X

precision

level controls use 10K stepped

attenuators

- as this level control value is common in the Pro Audio environment. |

| Actually, you

can also use a stepped attenuator value which is HIGHER

than the rated input impedance - this doesn't really hurt anything -

they are essentially just voltage dividers! So

don't worry about it if that's what you end up with. The sound quality

will typically not be noticeably affected. |

|

Goldpoint

Standard stepped attenuators of any value will always sound better

than

potentiometers -

due

to the transparent sonic quality of the Thin Film Nichrome resistors we

use on them.

|